What’s the Necessaries to Build a Professional Dry Ski Slope for Skiing and Snowboard

Dry ski is originated in England. The birth of dry skiing is a spatial and temporal extension of real snow skiing, which breaks the natural rule that skiing can only be done in low temperatures in winter. The skiing principle of the dry ski mat is accomplished by a combination of physical principles that allow objects on the slope to use friction reduction and friction increase to quickly slide and stop. At room temperature, the surface lubrication effect of dry ski can reach 90% close to real snow. Because dry skiing is not affected by any time season and geographic location, can be built in the southern region of the population flow of scenic spots and urban suburbs next to become the people weekend holiday leisure sports place. As well as children's entertainment and fitness training skiing hobby of a good place. Dry skiing can not replace skiing on real snow, but it allows more people to learn to ski, and convenient, and safe.

Dry ski facilities on the ground technical requirements

① Natural slope, the site needs to be leveled in accordance with the requirements of the design drawings, in the cast-in-place 10 cm thick concrete.

② The flat ground needs to do steel structure, and a dry ski mat can be installed directly on the steel board.

③ Cannot harden the lawn or compacted slope, can customize the special base of the dry ski mat.

④ Slopes covered with gravel on the land should have horizontal and vertical even (about 2m spacing) fixing points, either concrete stakes or wooden stakes (pre-built pieces or something) to be used to fix our dry ski mat. Let the dry ski mat will not fall down due to the force.

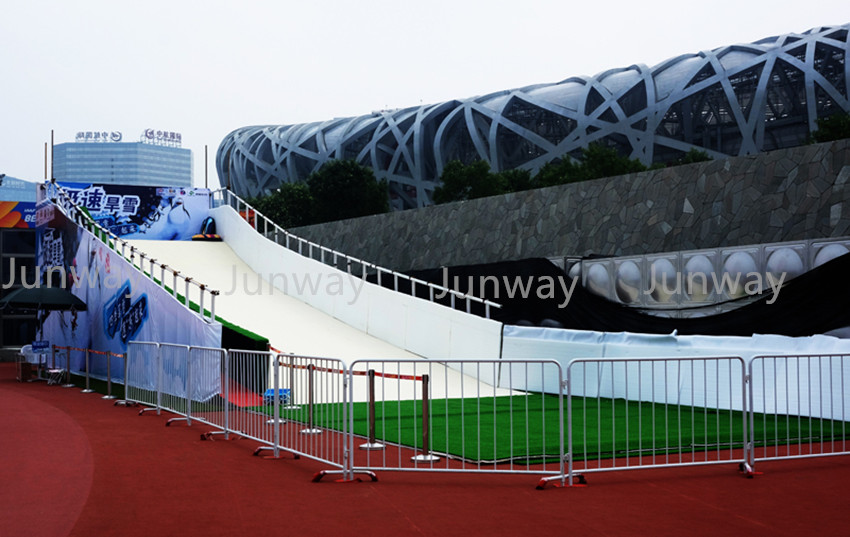

In addition to the dry ski mat, what other supporting facilities are included?

1. Snow Track Foundation:

① Slope built by a steel structure.

② The dry ski slope was constructed by naturally broken.

③ Use the roof of the building, and the building is one of the dry ski slopes.

④ A dry ski slope built with temporary construction materials.

2. Carrying tools (dry snow magic carpet, towing, ropeway, etc.)

3. Protection facilities (guardrails, fences, and crash walls).

4. Snow hall, supporting service room building.

5. Lighting, sound system.

6. Sprinkler system.

7. Dry snow management hardware and software systems.

8. Ski equipment (double and single board, snowshoes, various storage racks, etc.).